1 / 1

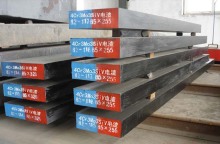

GB 40CrMnMoS86 / DIN 1.2312 / AISI P20 + S cetakan steel datar bar

| Brand Name : | Naik |

|---|

Deskripsi Produk

|

Size Available: Plate: Thickness 40-350mm Width100m-1000mm Length 2m-6m Round: Dia. 60---800mm

Listing Description 1. EAF-LF-VD-ESR Forged 2. ISO 9001 certificated 3. Factory direct sales steady supply 4. Higher resistance to heat checking Detailed Description Characteristics: Round P20+S is with additional sulphur, usually supplied in a quenched and tempered condition. Polishable, better machinability compared to 1.2311 Applications: Round P20+S is for making plastic moulds, frames for plastic pressure dies, hydroforming tools

SetaraKelas:

Komposisi kimia(untuk referensi saja):

Jaminan kualitas: Kami adalah ISO 9001: 2000 otentikasi perusahaan dan kami dapat memberikan jaminan tertulis perusahaan kualitas untuk semua produk diekspor Permukaan kondisi:Black permukaan / berubah / penggilingan / peeling / Poles. Kekerasan:Annealed HBS220 max Berat: 20meter: GW: 17.5T; (5.69mX2.13mX2.18m) 40ft: GW: 22T; (11.8mX2.13mX2.18m) Perlakuan panas P20 + s bulattment bulat P20 + s

Keunggulan kami: 1. baik kinerja dalam memeriksa panas 2. berbagai ukuran besar untuk pilihan pelanggan 3. nice keuntungan dalam hal mengejutkan termal melawan 4. ESR membuat yakin kualitas ketika pengiriman 5. hitam & Anil, kupas, atau berubah opsional 6. produsen dengan teknologi canggih dan kontrol kualitas yang baik 7. Selamat datang untuk mengunjungi pabrik kami besar setiap saat | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Produk Tags: paduan die baja steel datar bar | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||