1 / 6

OEM Service Steel Casting Train Parts Company

Ningbo, Zhejiang, China

- Pabrikan

- Layanan OEM

- Pemasok Emas

- Sertifikasi Platform

- Ekspo online

Deskripsi Produk

OEM Service Steel Casting Train Complemys

Implementa Pertanian Suku Cadang Mesin Pertanian Cor Bagian Baja dan Pabrik Casting

Didirikan pada tahun 2010, area tanaman mencakup sekitar 5.000 meter persegi, dengan sekitar 60 karyawan.

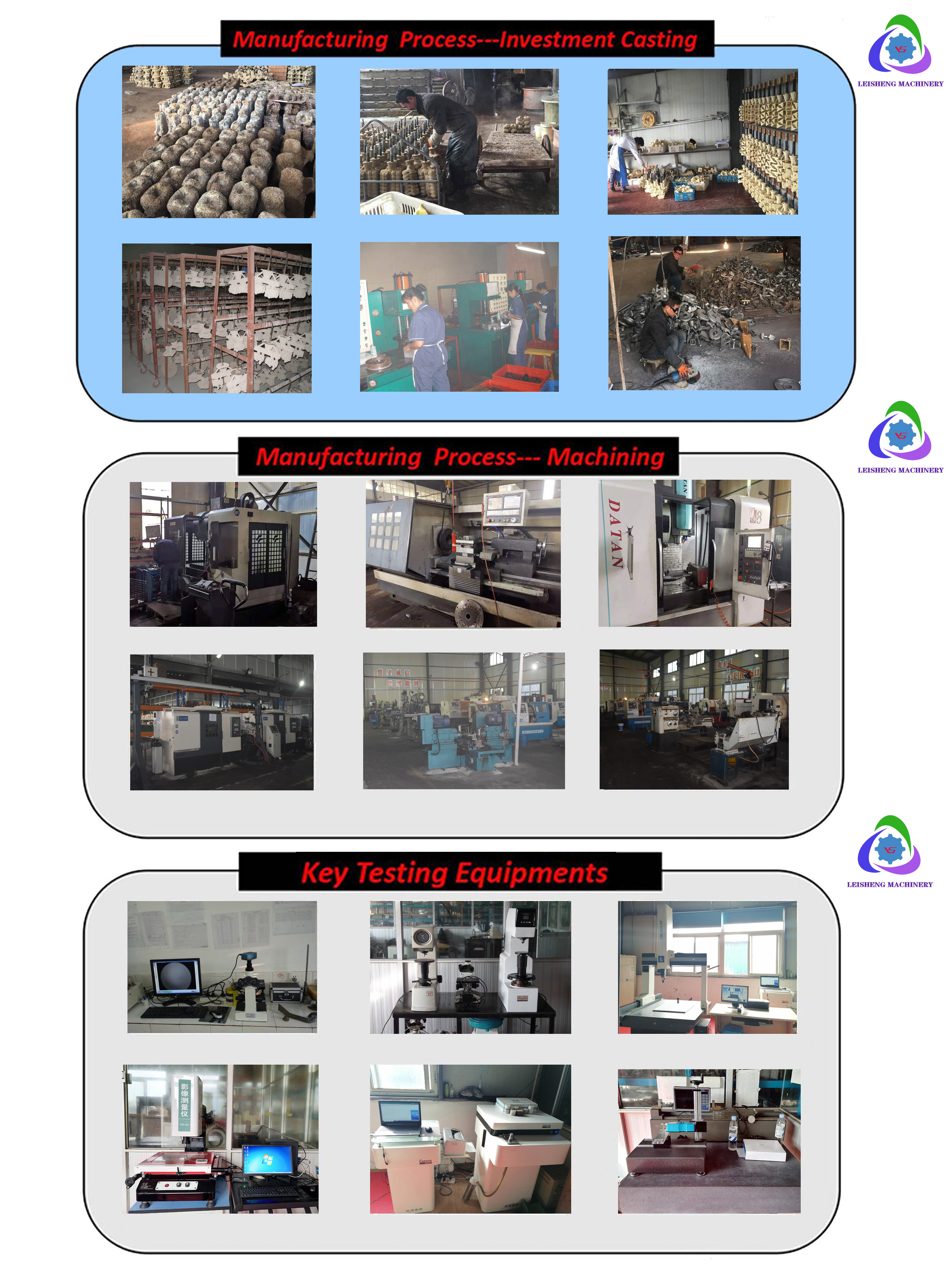

Dilengkapi dengan peralatan pemesinan CNC canggih lengkap, termasuk 30 pusat vertikal dan horizontal, dan lebih dari 30 mesin CNC dan 50 peralatan permesinan lainnya.

Fasilitas pemesinan sepenuhnya independen dari pengecoran casting dan memiliki tim manajemen independen dan model bisnis yang disesuaikan. Selain casting, penempaan dan pemesinan, ia juga memiliki fasilitas untuk mesin berbagai profil.

Menggunakan proses casting investasi lilin yang hilang, dilengkapi dengan beberapa jenis modern hemat energi & jalur produksi yang ramah lingkungan, termasuk jalur produksi otomatis atau semi-otomatis dari proses utama: pembuatan lilin, pembuatan cangkang, tuang, perlakuan panas.

· Kapasitas pasokan tahunan adalah 15.000 ton.

1. Tinjauan Umum Pabrik- Leisheng Machining & Casting Investasi

2. Misi kami:

Mencapai impian Anda dengan kecerdikan. Buat Masa Depan Anda dengan Pemesinan Presisi

3. Nilai -Nilai Kami:

· Bergerak dengan waktu

· Perintis dan Inovasi

· Harmoni dan Win-Win

· Berusaha untuk keunggulan

4. Deskripsi Produk:

|

Material |

Carbon steel, alloy steel, stainless steel |

|

Process |

Lost wax casting + cnc machining |

|

Casting dimension tolerance |

CT7 |

|

Casting surface roughness |

Ra 12.5um |

|

Casting weight range |

0.1-90kg |

|

Casting Size |

Max linear size: 1200mm, Max diameter size: 600mm |

|

Machining Precision |

Positioning accuracy 0.008mm, Rep. position. accuracy 0.006mm |

|

Machining surface roughness |

Ra0.8~6.3um |

|

Max Travel Of Spindle |

1800mmx850mmx700mm |

|

Max Turning Diameter |

1000mm |

|

Material standard |

GB, ASTM, AISI, DIN, BS, JIS, NF, AS, AAR....... |

|

Surface treatment |

KTL(E-coating), Zinc plating, Mirror Polishing, Sand Blasting, Acid pickling, black oxide, Painting, Hot galvanizing,Powder coating, Nickel plating |

|

Service available |

OEM & ODM |

|

Quality control |

0 defects,100% inspection before packing |

|

Application |

Train & railway, automobile& truck, construction machinery, forklift, agricultural machinery, shipbuilding, petroleum machinery, construction, valve and pumps, electric machine, hardware, power equipment and so on. |

5. Proses pembuatan:

Process design⇒ Tooling making ⇒ Wax injection ⇒Wax pattern assembly⇒ Mold preheat ⇒ Wax removal ⇒Stuccoing ⇒Dipping Casting⇒ Mold shake out ⇒Work piece cut-off ⇒ Grinding ⇒ Pack& transport ⇒ Final inspection ⇒Machining ⇒ Heat treatment

6. Kami menyediakan berbagai fasilitas pengujian seperti yang disebutkan di bawah:

|

1. Chemical analysis |

|

2. Tensile strength |

|

3. Elongation rate |

|

4. Shrinkage rate |

|

5. Impact test |

|

6. Harness test |

|

7. Metallography |

|

8.Non-destructive tests(including dye-penetrant, ultrasonic, magnetic particle and radiography) |

|

9. Surface roughness test |

|

10.CMM test |

|

11.3D Scanning |

7. Keuntungan Kompetisi Inti:

|

Advantages 1:High Engineering and Technical Capability |

· An industry's senior engineering technical team , with special skills and rich experience in product design, casting ,heat treating and machining fields. · Based on customer needs, in the beginning of product development, offer a solution, casting design, by structural component designed to casting parts, optimize the product design, then reduce costs and creating the more value for the customers. · Special Techniques Enable us to Be Competent with Those Difficulties at Wax Injection & Shell Making Procedures When Manufacturing the Parts with Inner-Sophisticated-Structure. · Use casting simulation analysis system software , try our best to to ensure the success of the one-time trial sample. · |

|

Advantages 2: Advanced Inspection Equipment & Strong Quality Assurance Capacity |

· Our testing equipments are not only advanced in the industry, and also has a very complete range, they are hardware guarantee to ensure us continue to provide high-quality products for our customers. · Carrying out ISO9001 quality management system, full implementation of 5S and Kanban site management, which is software guarantee of the quality. · IQC, IPQC and FQC quality management team to control the whole production process, effectively prevent the generation of unqualified product. · Our casting' PPM ≤1000 Machining ' PPM ≤600 · We stick to the quality management philosophy that “Starting from the customer needs and ending with their satisfaction, focusing on customer demands and exceeding their expectations”. |

|

Advantages3: Good Customer Service |

· LEISHENG can provide customers with good service, our staff have abundant commercial experience, good language ability, and rich foundry or mechanical background. We are committed to providing customers with accurate, careful and speedy service. · Quotation, Quality Complaints and Email Response can usually be quickly and efficiently feedback within 48 hours. · · We have carried out an information-based management which is driven by an ERP and PMC system, to ensure on time delivery rate: 95% |

|

Advantages 4: Powerful Deep-processing Ability It is the important core competitive ability for QIANHAO |

· Machining capability as the same as casting, the machining facility is fully independent from the casting foundry and has an independent management team and tailored business model to suit. · LEISHENG has completed a transformation and upgraded to a deep-processing manufacturer with expanded production capabilities and is committed to be equipped with other capabilities except casting, we focus on developing terminal products for top-end markets. · High technical content in machining, and casting with sheet metal, welding, assembling, LEISHENG has the more competitive advantage, it is the very good choice for you. |

8. Informasi Kontak:

Ningbo, Zhejiang, China

- Pabrikan

- Layanan OEM

- Pemasok Emas

- Sertifikasi Platform

- Ekspo online

Kirim pertanyaan Anda ke pemasok ini