Video

1 / 4

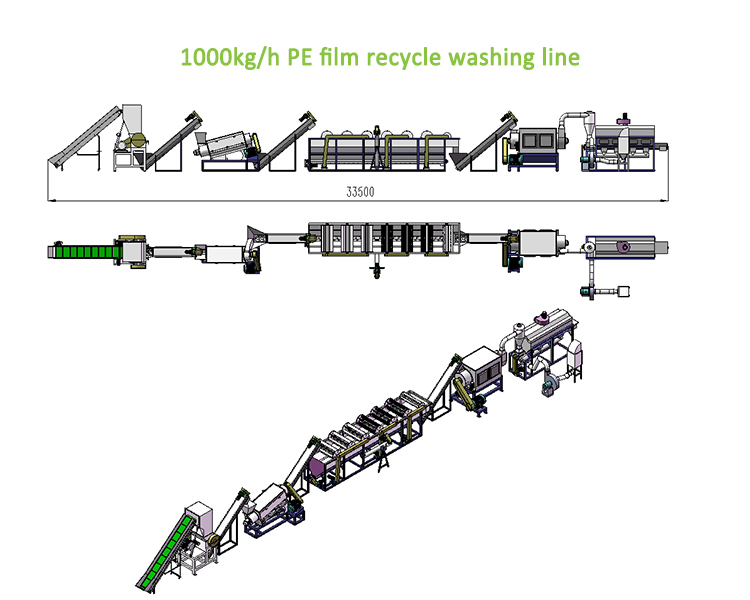

Mesin Cuci Daur Ulang Film PE / PP Pertanian Limbah

$80000.00

≥1 Set/Sets

$50000.00

≥2 Set/Sets

Model:

- BDX300

- BDX500

- BCX1000

- BDX1500

- BDX2000

| Model No. : | BDX-1000 |

|---|---|

| Brand Name : | Mesin Sevenstars |

| place of origin : | China |

Deskripsi Produk

Mesin Cuci Tas Film PP PE terutama digunakan untuk memproses plastik lunak seperti kantong plastik dan film plastik. Selain itu, ia juga dapat menangani plastik keras PP PE. Termasuk penghancur, pengumpan, dewater, tangki pembilasan, Penghancur Poros Ganda, dan mesin lainnya.

1 0,1 karakteristik Material

Bahan yang akan dirawat adalah film PP PE dengan kontaminasi:

● Label

● Residu konten film asli

● Logam, debu atau pasir terakumulasi selama transportasi atau permanen di udara

Bahannya bisa dalam bal atau longgar, operator harus membuka bale sebelum memasukkan material ke dalam jalur.

Produk jadi: bersihkan serpihan PP PE.

Tahap selanjutnya: Mesin Pelet Tas Film PE PP.

Selain itu, pabrik kami memiliki Mesin Daur Ulang Plastik lainnya.

1.1 Bahan baku & produk akhir:

|

Raw material & formulation |

Waste PP woven bag and PP jumbo bag and PE film..etc |

|

Final product & Output capacity |

Input capacity : around 600-700kg/hour Clean dry PP scraps :500kg/h |

|

Description of final product |

Scrap size: 10-12mm |

1.2 Kondisi kerja

|

Warehouse/Workshop

|

Dimension (M*M*M): 35(L)×5(W)×4.5(H); Crane: Machine positioning(provide by customer) |

|

Power supply & Installation power |

3-phase, 380V, 50 Hz; |

|

Wire/cables(provide by customer) |

Wires/cables from power supply to control cabinet of this production line; all electrical cables from control cabinet to each machine. |

|

Water supply hose/pipe(provide by customer) |

Water supply to machines and pools |

1.3 Konsumsi energi

|

Installation power |

Max 200KW (Actual power consumption percentage: 70-80%) |

|

Water supply |

Consumption: about 5 ton/h, can be recycled use, Water pressure: 0.4Mpa |

|

Manpower |

3-5 Persons (1-2 persons for feeding, 1-2 persons for collecting the finished PP scraps,1 person(skilled) for controlling the cabinet) |

Video

Kirim pertanyaan Anda ke pemasok ini